ANC COMPONENTS

PASSION AND EXPERTISE & FINEBLANKING AND HIGH-SPEED PRESSING

We press and form steel & metal into high-tolerance components, transform them into products for the most demanding technical applications.

They are used everywhere from the electrical and automotive industries, energy, heavy transport technology and mechanization, in hydraulic systems and in mass produced household appliances.

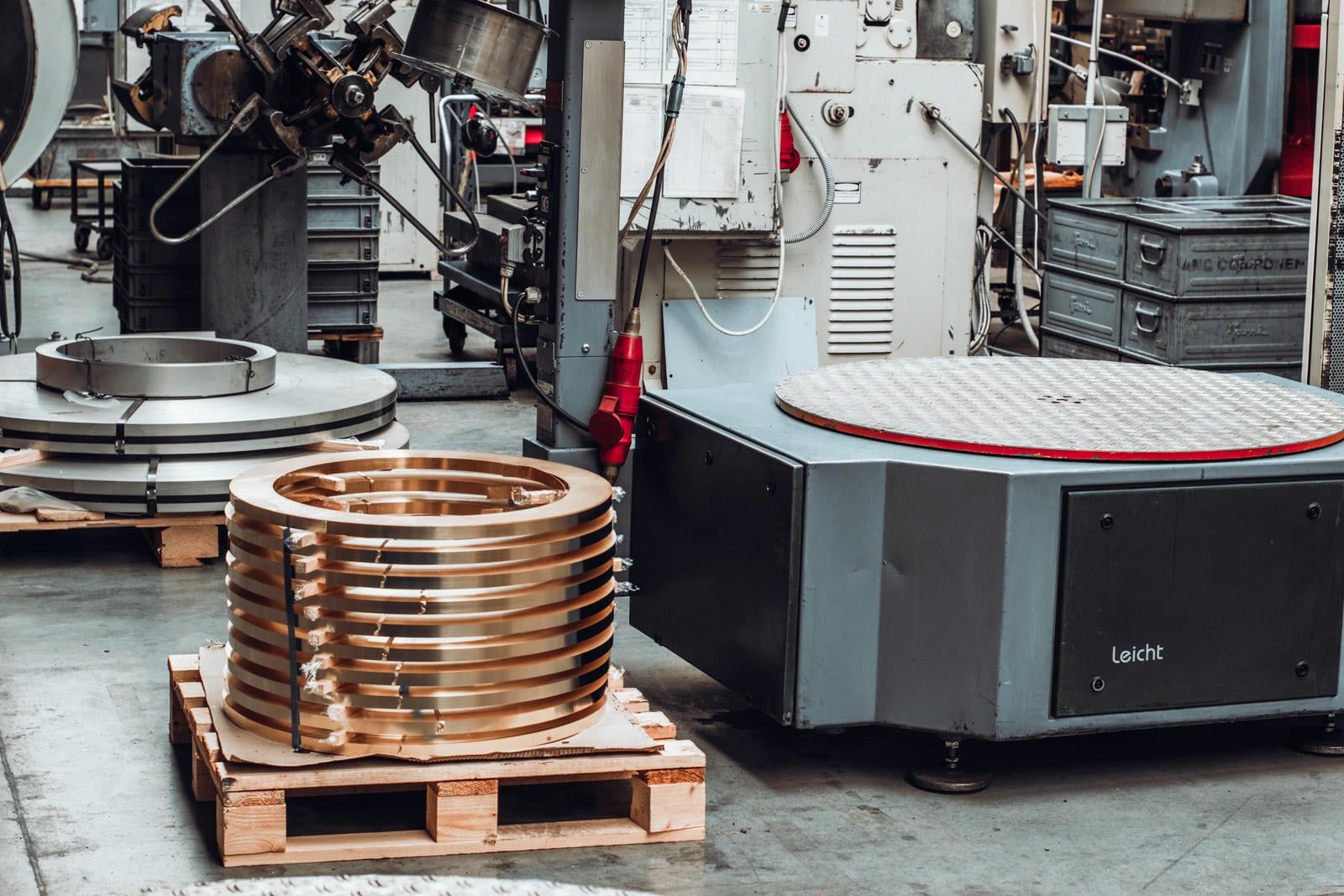

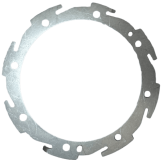

OUR PRODUCTION OF PRECISE METAL COMPONENTS

You usually don't see our products, they are part of other components and more complex assemblies.

They help in power transmission, conduct media, participate in the control of vehicles or industrial systems. The list can be endless, but they always have one thing in common: production in large series, with strict tolerance requirements, at the beginning there is always an investment in a pressing tool.

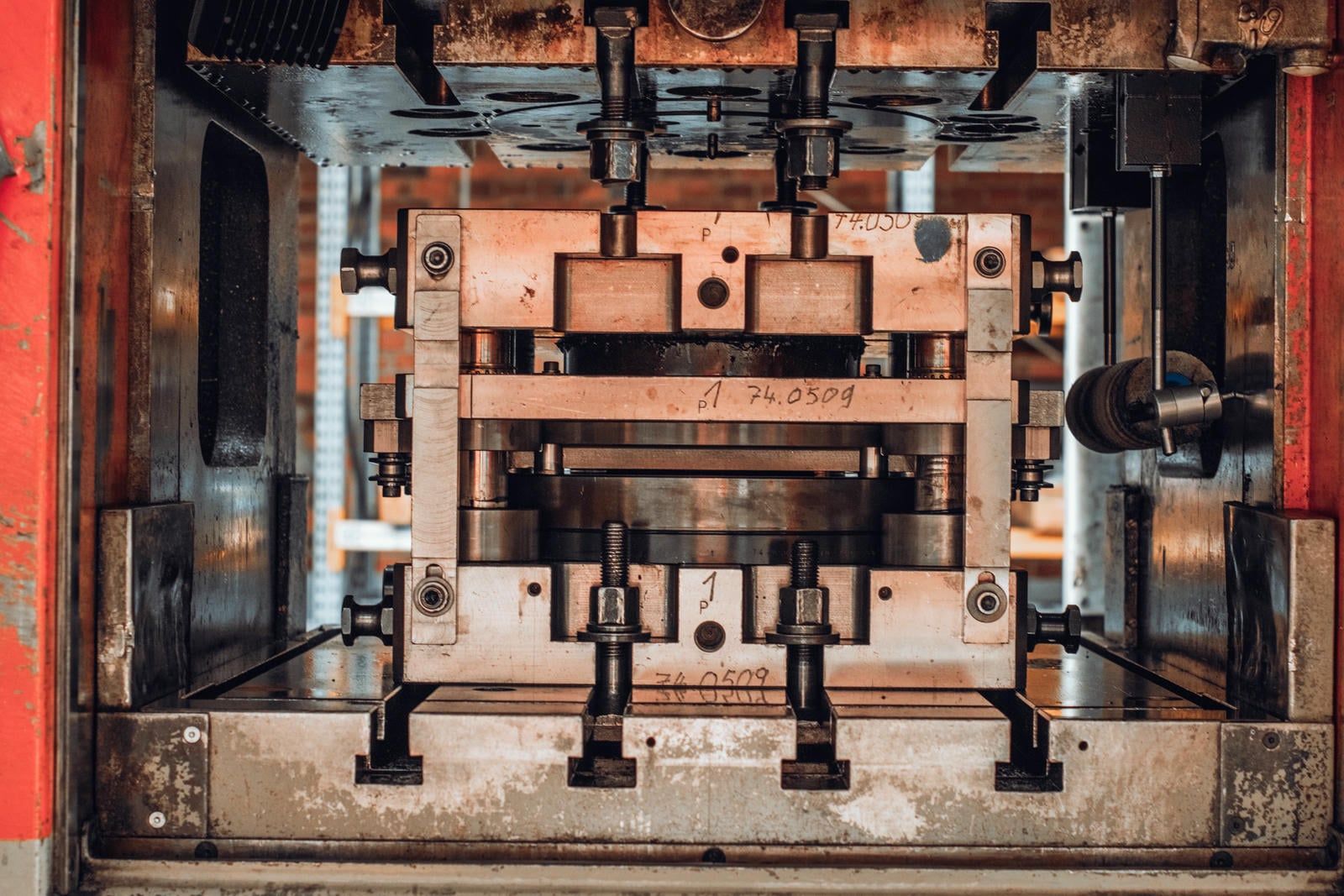

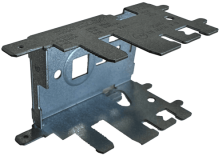

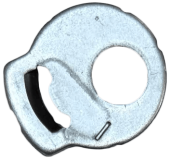

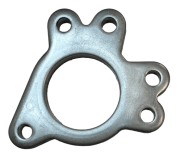

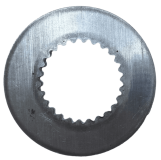

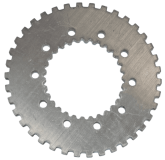

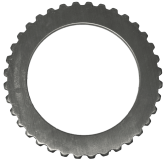

FINEBLANKING

TECHNOLOGY

TECHNOLOGY

We press and form using precision cutting technology on top-of-the-line Swiss Feintool presses.

Volumetric forming, significantly higher cutting surface quality, tighter tolerances and superior precision: setting fineblanking apart from conventional presses.

With just one stroke, we can replace several chip machining operations.

-

Available tonnage 160 – 630 t

-

Typical productivity 25 – 40 strokes / min

-

Raw material thickness up to 10 mm

-

Own development of tools

-

Experience with stainless steel processing

-

Finishing: deburring or grinding

-

Productivity up to 1000 strokes/min

-

Tolerance range: ±0.01 mm

-

Rewindable transport tape option

-

Steel, non-ferrous metals, spring stainless steel

-

Own tool design

-

Production series > 100,000 pcs / year

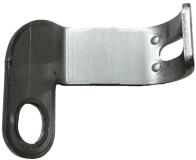

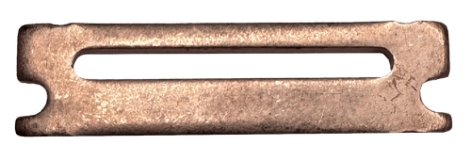

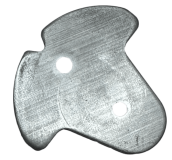

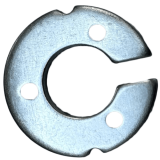

HIGH-SPEED

STAMPING

Unprecedented productivity and precise, sustainable accuracy.

We entered this world with proven Bruderer presses.

HIGH-SPEED

STAMPING

Unprecedented productivity and precise, sustainable accuracy.

We entered this world with proven Bruderer presses.

-

Productivity up to 1000 strokes/min

-

Centimeter tolerances

-

Rewindable transport tape option

-

Steel, non-ferrous metals, spring stainless steel

-

Custom tool design

-

Production series > 100,000 pcs / year

ROBOTIC

WELDING

We add additional value to the production of our own pressing plant.

Welding robots now operate independently, requiring minimal human intervention.

Are your standards high? You’ll appreciate their precision, speed, and consistency.

-

MIG/MAG, TIG method

-

Accuracy & repeatability

-

High productivity & low costs

-

Robust construction

-

Fanuc industrial robots